The C(P)SCD series marine transformer is designed for installation on ships, marine platforms, and other locations, serving various applications such as lighting, safety isolation, secondary power control, and equipment power supply under normal operating conditions.

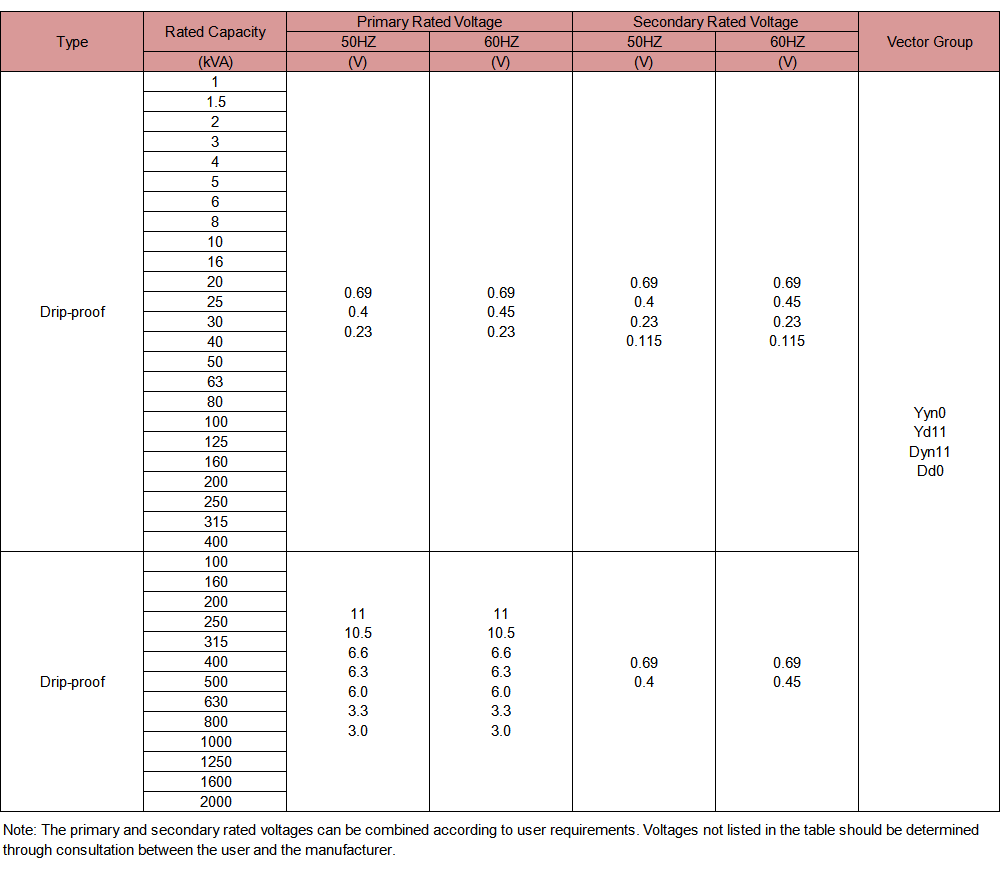

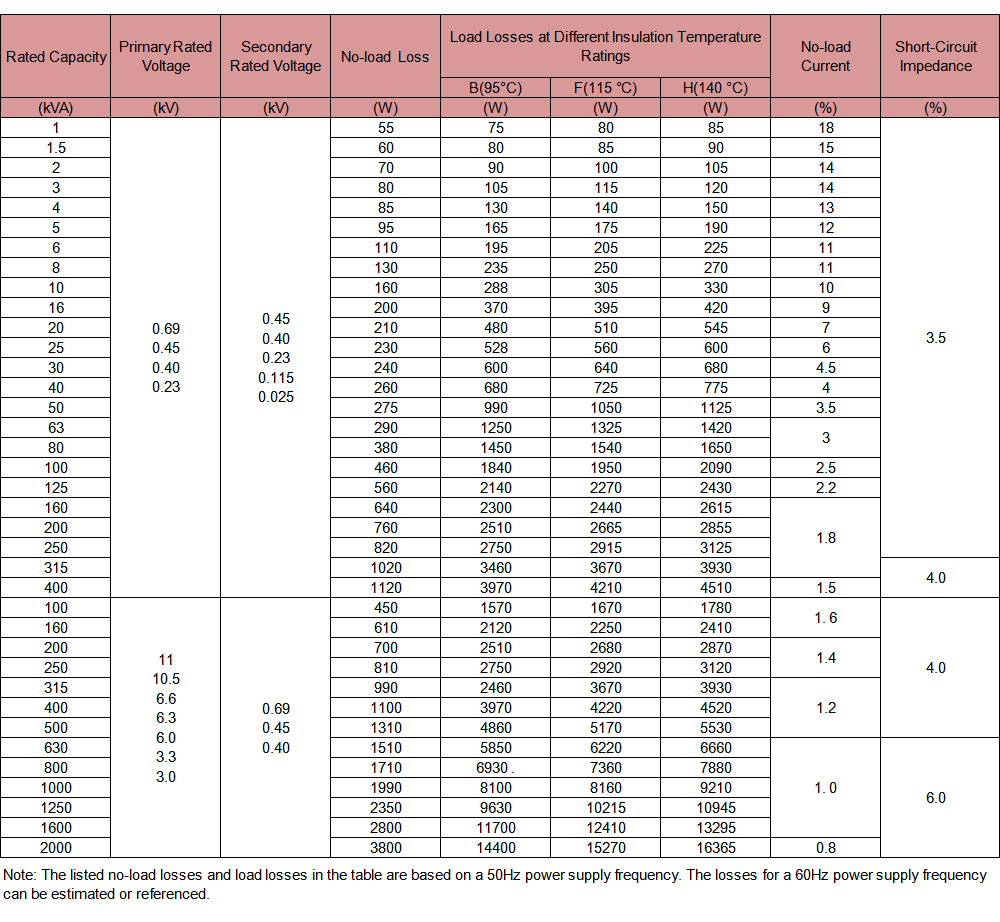

These marine transformers are suitable for voltages up to 11kV, with frequencies of 50Hz and 60Hz, and insulation classes of B, F, and H.

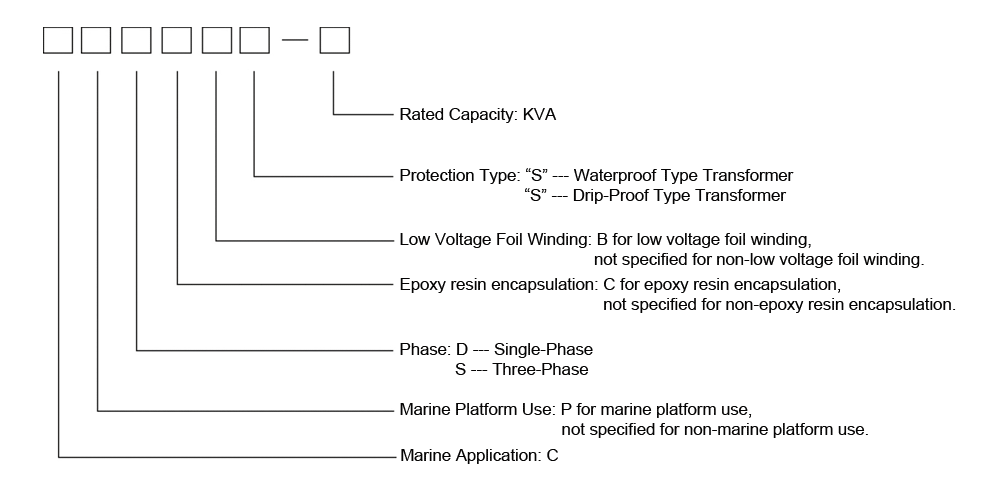

Featuring three-phase marine transformers with a capacity range of 100 to 2000kVA, the C(P)SCD series provides versatility for different power requirements. It is available in various protection classes, including drip-proof IP22, IP23, IP44, or waterproof IP55 types, ensuring reliable performance in different environmental conditions.

◆ Ambient temperature: -25 to +45°C.

◆ Relative humidity: not exceeding 95%.

◆ Influence of condensation, oil mist, salt spray, and mold.

◆ Vibration and impact generated during normal operation of the vessel.

◆ Roll angle of the ship during operation: ≤22.5°, tilt angle: ≤15°.

◆ The waveform of the power supply voltage is approximately sinusoidal, and the voltage supplied to the three-phase transformer is approximately symmetrical.

◆ Superior Insulation

The coils are wound with high-quality insulated wires or enamel wires using a spiral winding technique with ventilation ducts, allowing for better internal heat dissipation.

◆ High Voltage Transformer Coils

The coils are constructed using multiple layers of fiberglass mesh fillers, vacuum impregnated with epoxy resin, to significantly enhance electrical strength, improve short-circuit resistance, reduce partial discharge, provide flame retardancy, and enhance the "Three Protections" performance against moisture, salt spray, and mold.

◆ Core Selection

High-grade, low-loss silicon steel laminations are used for the core. The laminations are carefully stacked at a 45-degree angle in a seven-step-lap configuration, resulting in reduced magnetic leakage, low noise, low losses, and reduced mechanical vibrations.

◆ Enhanced "Three Protections" Performance

The entire transformer body undergoes multiple layers of vacuum impregnation, and special techniques are employed for electrical and mechanical connections to enhance its protection against moisture, salt spray, and mold.

◆ Transformer Enclosure

The transformer enclosure is made of stainless steel or hot-dip galvanized steel sheets, with a surface coating of anti-static paint. The design ensures adequate airflow while effectively preventing water ingress and the entry of rodents. The enclosure protection level is IP22 or higher.

◆ Terminal Blocks

The terminal blocks are located inside the transformer enclosure, allowing cables to pass through waterproof cable glands and be securely connected to the terminal blocks. For high-capacity transformers, the incoming and outgoing cables are typically positioned at the bottom. Cable holes are provided in the transformer base, along with devices to protect the cables from abrasion and keep them firmly in place.